What lies behind the “comfort” of Japanese-made body towels?

We visited a rare factory that manages multiple processes in-house—from traditional Hatcho twisting machines to the latest automatic packaging lines. This report offers a photo- and video-rich glimpse into the factory where analog craftsmanship coexists with digital precision, and where Japan’s traditional manufacturing spirit lives on.

A Day Begins in Kiryu – Local Flavors and Warm Hospitality

Fueling up with local salt ramen

On the afternoon of July 16th, President Nagatake greeted us at ASHIKAGA Station. Having not eaten during the long journey, we first headed to lunch at his favorite local spot, Ramen Miyabi. The clear salt-based soup, flat hand-kneaded noodles, and the gently sweet flavor of charred chashu combined to form a bowl that felt like “slurping Kiryu’s artisan spirit.”

The empty stomach from the long travel was instantly satisfied, and our excitement for the factory visit grew. The quiet, untouristy atmosphere near the station resembled the peaceful countryside of Wakayama, adding even more charm to the experience.

A One-Stop Factory Where “Efficiency Equals Quality”

We began with a meeting at headquarters, exchanging ideas while actually testing foam differences based on yarn twist. Concepts such as bold package designs and hybrid towels with mixed materials emerged quickly.

Afterward, we toured a rare integrated production site, where twisting, knitting, sewing, and full inspection are all performed on one premises. The presence of many foreign workers—fluent in Japanese and highly diligent—was striking. President Nagatake, planning a Southeast Asia visit for recruitment, is proactively advancing global employment.

What impressed us most was the high level of automation: many operations were run by a surprisingly small and efficient team. Their well-thought-out approach to solving labor shortages through technology was deeply instructive.

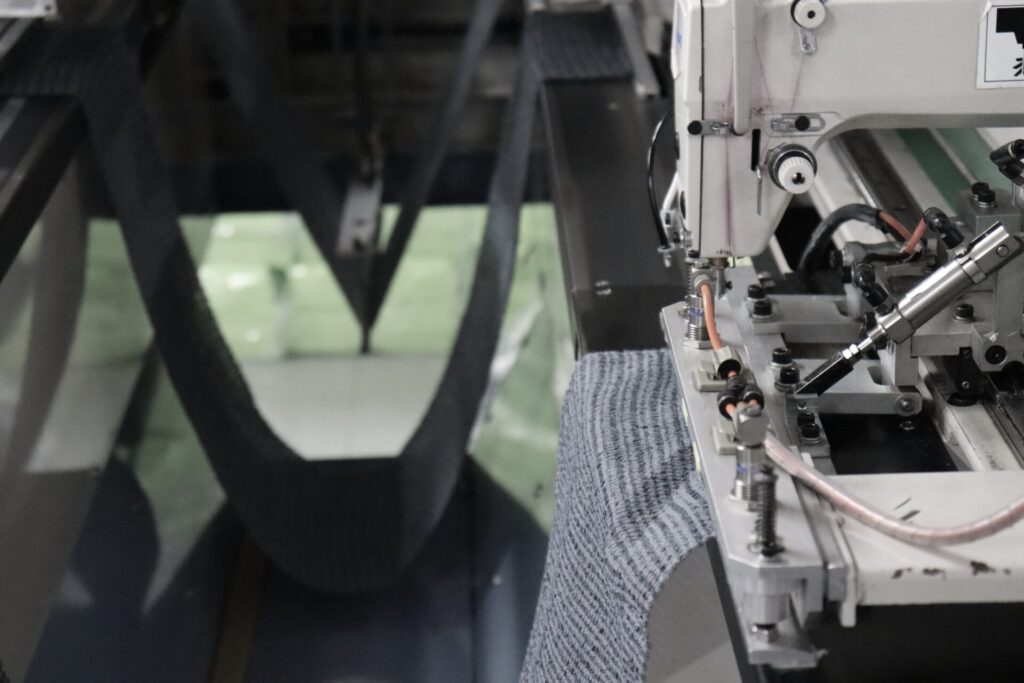

We first encountered a vintage Hatcho twisting machine inherited from a now-defunct company. Its very presence whispered of the past. Nearby, a newer Raschel knitting machine created fabric under the watchful eye of a single operator managing multiple machines.

The coexistence of old and new machines in the same space emphasized that both speed and finesse are key to achieving lather-rich, elastic fabrics. The commitment to preserving and maintaining these machines speaks volumes about Japan’s manufacturing resilience.

会社から譲り受けたもの

Twisted yarn is fed into both modern Raschel knitters and air-jet looms. Raschel machines create looped, volumized fabric; air-jet looms ensure smooth, high-precision finishes. Together, they form a unique dual system.

The Invisible Finishing Touch

After knitting, the fabric is gently compressed by a rugged heat press. This process flattens textures without damaging the material, adding firmness and dimensional stability. This invisible detail elevates the final product’s quality.

Dyeing Area – Five Minutes on Foot, Full of Craftsmanship

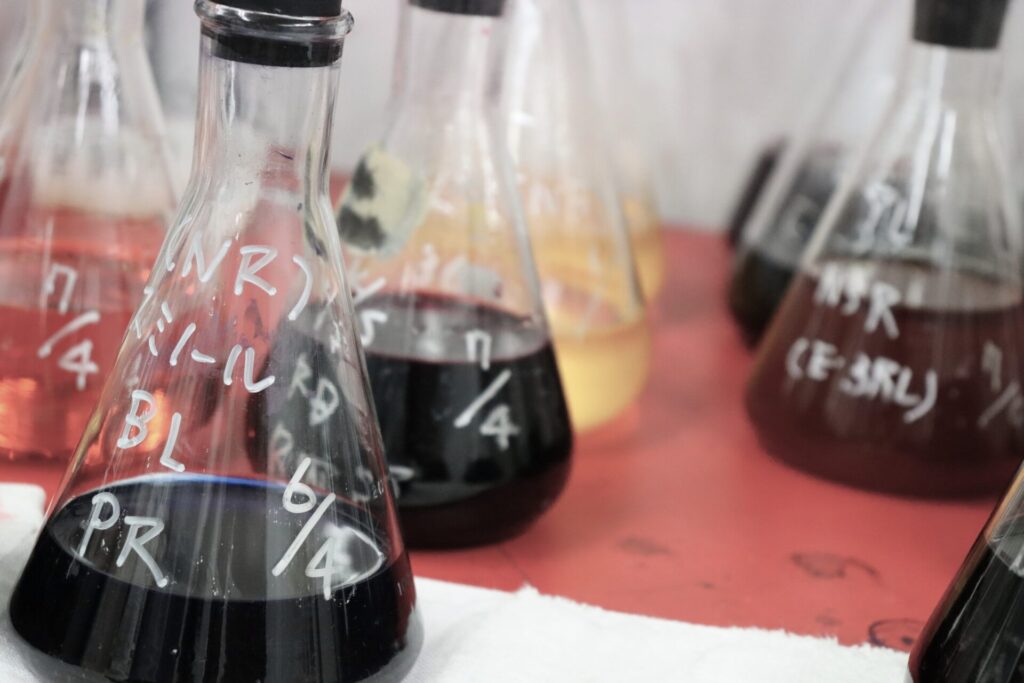

After leaving the twisting and knitting building, we walked five minutes through a quiet residential area to reach the dyeing building. Small liquid-flow dyeing machines gently knead the fabric as they color it. While workers were not active during our visit, we learned the system allows for on-site test dyeing and precise color adjustments—eliminating common outsourcing issues like mismatched sample and production colors.

Though modest in appearance, this meticulous attention to final quality truly embodies the strength of Japanese craftsmanship.

Automated Inspection and Folding: Natural and Precise

After dyeing and drying, towels are inspected for creases or stitching issues. Automatic equipment checks the size and shape, minimizing risks of contamination or stitching errors. Since this step determines the product’s “face,” both mechanical and manual inspections are essential.

On the conveyor belt, each towel is lifted and folded with such finesse that it mimics the handwork of skilled craftspeople.

Silk-Screen Printing: 800–1,000 Sheets Daily, Final Judgment by Hand

At the processing building, we observed a two-layer silk screen printing system. Operators align each towel by hand and apply ink using a squeegee, revealing vivid patterns instantly.

The towels are then dried using Aisen-made parasol hangers donated to the factory.

Despite the manual process, the line consistently produces 800–1,000 towels per day—an impressive feat.

(Note: Since another brand’s product was being printed, no photos or videos were taken.)

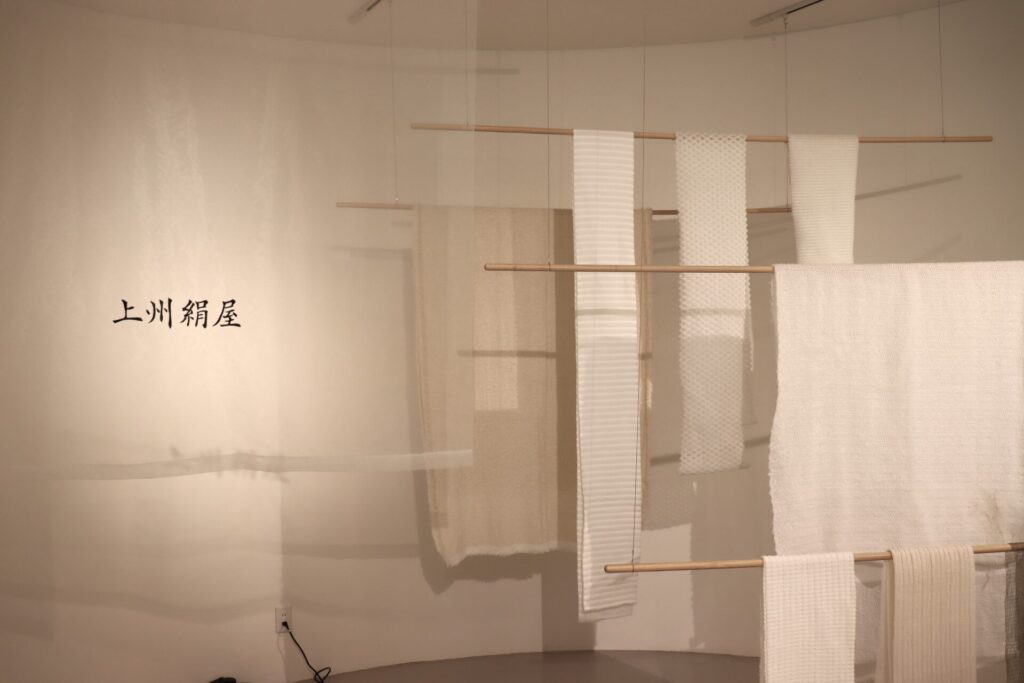

“Gunma 200” and Sericin – 500kg of Cocoons Telling a Rare Story

Although we couldn’t enter the cocoon room, we viewed detailed materials and video documentation. The rare silkworm breed “Gunma 200” produces about 500 kg of cocoons annually, of which about 100 kg becomes raw silk for the Joshu Kinuya brand.

The key: sericin.

Sericin is a natural protein surrounding silk fibers, known for its moisturizing, anti-static, and glossy benefits for skin and hair. Since most silk products remove sericin during processing, those that retain it are rare even globally. With Japan’s total raw silk output at only 9 tons per year, Miyama’s 100 kg is over 1% of the national supply—making it exceptionally rare.

Joshu Kinuyo – Nurturing Towels that Embrace Your Skin

Launched in 2015, the Joshu Kinuyo brand features 24 SKUs including sericin-rich body towels, mitts, and cocoon-shaped products.

Their unique texture clings softly to the skin, like a cloth infused with lotion.

Not machine-washable, but gently hand-washable with shampoo or conditioner thanks to its human-skin-matching pH.

Even used aboard luxury cruise ships and high-end select shops, the brand’s story aligns with aisen’s Fun to Clean philosophy—enjoying and cherishing everyday living.

やわらかな光に浮かぶ

上州絹屋の世界

養蚕の営みと職人技

Kiryu Nights – A Taste of Local Heart at “Satsuki” Izakaya

At the end of our visit, we enjoyed dinner at local izakaya Satsuki, recommended by President Nagatake. A regular customer from Bangladesh passionately described Japan as “the world’s cleanest and most comfortable country,” and the warm mood of the shop echoed the craftsmanship and hospitality we had witnessed that day.

People in Kiryu, like their products, are thoughtful and kind. With one last toast of Asahi Beer, the visit ended in pleasant afterglow.

“さつき”

◆Conclusion

From in-house sericulture to end-to-end production, from the hidden value of sericin to the warm hearts of the people of Kiryu — every piece reaffirmed the strength behind aisen’s Fun to Clean philosophy.

Aisen Industrial Co., Ltd.

Sales Department – Kohei Maeji

Tel: +81-734-87-4345

258 Onoda, Kainan City, Wakayama 642-0014, Japan