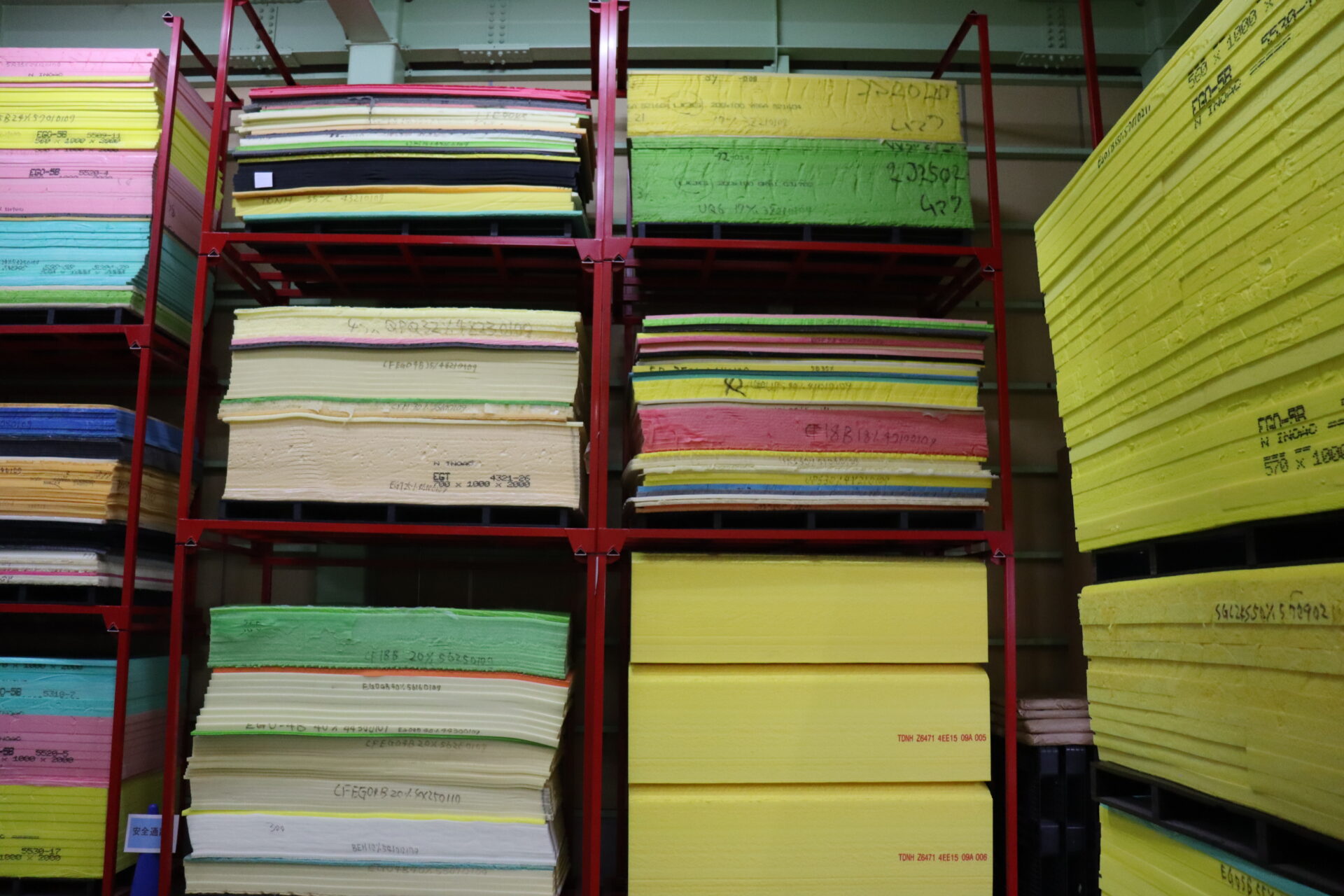

Storage Racks

Colour-coded racks hold urethane foam blocks in various sizes and densities for streamlined inventory management.

- Efficient organisation by size and density.

- High-mix, low-volume inventory control.

- Improves traceability and reduces waste.